An AFM is an extremely versatile tool for engineers, researchers, and other professionals that need accurate imaging and characterization of specimens at the nanoscale. It allows users to measure mechanical, electrical, chemical, and a wide variety of other surface properties as each user’s needs dictates. It also provides considerable power to manipulate atoms and molecules which lets users build structures and fabricate materials at nanoscale resolution.

THE PROBLEM WITH CURRENT AFM TECHNOLOGY

Despite this extraordinary power and versatility, AFM technology adoption has been relatively slow. This is largely due to the complexity of the systems and the learning curve to use them effectively. The first generation of AFMs, created during the time Park Scientific Instruments was born, were primarily focused on making the technology work reliably and produce consistent results. These early systems, though offering unprecedented resolution in nanoscale imaging, were difficult to use and required highly specialized training.

The second generation of AFMs focused on improving the versatility and accuracy of AFM technology. This is when AFMs began incorporating more varied measurement techniques to address ever growing research needs. It is also when Park Systems introduced True Non-Contact mode, a non-contact scanning technology in ambience, allowing users to image samples without touching them. This advancement greatly improved AFM technology, providing sharper and accurate atomic and molecular resolution imaging, maintaining tip sharpness, preserving the sample and saving expenses on probe replacements. Furthermore the ability of non-contact technology that also senses force from the sides (instead of only from the bottom in case of contact or tapping mode), improved the imaging versatility. However, these advances did little to fundamentally improve the usability of AFMs. The technology required time consuming hands on approach by professionals with specialized training.

PARK SMARTSCAN MARKS THE NEW ERA OF AFM TECHNOLOGY

In the way the point-and-shoot technology in today’s camera revolutionized the photography world, Park SmartScan will revolutionize AFM technology by introcuding simplicity into www.nano-scientific.org NANOscientific 7 AFM systems. Just like with a point-and-shoot camera, with Park SmartScan in Auto mode, the user points to the area of interest and clicks a button to automatically acquire a high quality image comparable to that taken by an expert at a fraction of time spent with the instrument.

MAKING TEDIOUS AND DIFFICULT IMAGING SIMPLER

Unlike previous AFM scanning technologies which have been limited to use by highly skilled professionals, SmartScan’s automatic technology greatly simplifies the scanning process, allowing nearly anyone to acquire top quality AFM images in high nano level resolution.

Compare this list of the steps necessary to typically operate a traditional AFM to those necessary to operate a Park SmartScan system:

Traditional AFM Opertaing Procedures:

1. Perform a frequency sweep to find the resonant frequency of the cantilever.

2. Select the optimal frequency from the sweep amplitude-frequency value by adjusting the drive magnitude while monitoring the frequency-amplitude graph.

3. Move the Z-stage down close to the sample surface while visually inspecting the tip and sample distance.

4. Lower the focus stage to see the sample surface.

5. Move the focus stage up to see the cantilever, and estimate the distance between the tip and sample.

6. Move the Z-stage down slightly.

7. Repeat steps 3-6 until the desired distance is achieved between the tip and the sample.

8. Select the region of interest to scan by moving the stage while observing the sample surface optically.

9. Make the “approach” by moving the Z-scanner further down until the cantilever tip is just above the sample (~10 nm for non-contact) or just touching it (contact scan).

10. Slowly lift up the Z-stage until signal in trace window is clear.

11. Make a second frequency sweep to optimize the frequency and amplitude value.

12. Repeat the approach for greater accuracy.

13. Do a “Line Trace” to decide on the optimum scanning parameter values based on the line trace data. The parameters that need to be set include Set Point, Z Servo Gain, and Scan Rate.

14. Scan the sample. If the image quality is not satisfactory, adjust scan parameters, and repeat above steps 2 to 14 again.

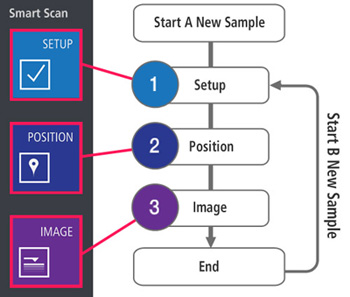

Park SmartScan Operating Procedures:  1. Click “Setup” - This opens a guided animation to help the user place the sample in position.

1. Click “Setup” - This opens a guided animation to help the user place the sample in position.

2. Click “Position” - This makes the system perform a fully automatic frequency sweep, z-stage approach, and autofocuses the image. User points the area of interest.

3. Click “Image” - The system will automatically adjust setting for optimal image quality, scan the sample, and produce the image. The Park SmartScan requires 3 straight forward point and click steps. Traditional AFM technology requires many iterative steps of complicated input from the user. With SmartScan technology, researchers and engineers can spend much less time on repetitive imaging and more time doing other work, greatly increasing their productivity.

HOW DOES SMARTSCAN WORK?

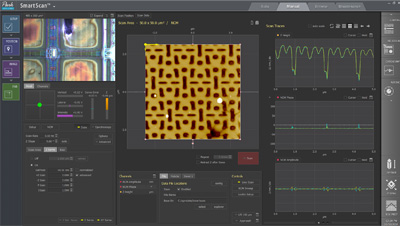

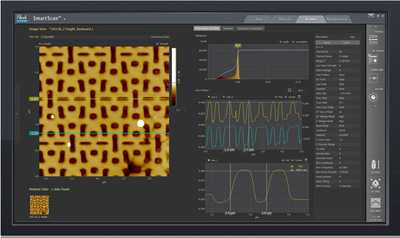

Park SmartScan autonomously executes all the steps of the imaging process. All the user needs to do is place the sample on the stage, choose the area of interest, and specify the scan size desired. The rest is done by SmartScan at a click of a button.

The system will automatically perform the frequency sweep for the cantilever, approach the Z-stage to the sample, and auto focus the sample allowing the user to see and navigate the area of interest for imaging. It will also set all the necessary parameters for optimum setting, engage the cantilever and start scanning the sample. The scan will continue with no additional action from the user until the image is acquired and completed.

BUT HOW DOES THE PROCESS ACTUALLY WORK, AND WHY IS IT ONLY NOW BEING IMPLEMENTED?

After placing the sample on the stage, the Z stage and the tip must be moved in extremely close to the region of interest. This is not an easy task. However, SmartScan technology uses Park’s own proprietary True Non-Contact AFM technology to help automate the process using the following two patent pending techniques, among others.

FastApproach™ technology

Park’s True Non-Contact capability allows the Z scanner to approach the sample automatically and at much higher speed than through a traditional manual approach. This technique, developed by Park Systems, is called FastApproach™. It monitors the amplitude change of the cantilever under resonance during the approach. This allows it to sense the exact moment to slow down and stop few nanometers above the sample.

AdaptiveScan™  AdaptiveScan adjusts the scanning speed to the sample topography dynamically to maximize scanning speed while retaining high image quality. This technique, also developed by Park Systems (patent pending), scans the first line at regular constant speed. It then scans the subsequent lines utilizing prior line scan information at variable speeds that adjust in real time. This technique is possible because of True Non-Contact™ mode scanning technology that senses force on the sides of the sample in addition to forces from below the sample, allowing adjustments to be made automatically on the fly. Park SmartScan also incorporates several other automation features to make the process more user friendly. Scripting and built in macros allow users to easily create own customized scanning automation, making more complicated repeated scan simpler. SmartScan is also designed with a cleaner, more intuitive user interface from ground up, making it easier to use, even by those without special training.

AdaptiveScan adjusts the scanning speed to the sample topography dynamically to maximize scanning speed while retaining high image quality. This technique, also developed by Park Systems (patent pending), scans the first line at regular constant speed. It then scans the subsequent lines utilizing prior line scan information at variable speeds that adjust in real time. This technique is possible because of True Non-Contact™ mode scanning technology that senses force on the sides of the sample in addition to forces from below the sample, allowing adjustments to be made automatically on the fly. Park SmartScan also incorporates several other automation features to make the process more user friendly. Scripting and built in macros allow users to easily create own customized scanning automation, making more complicated repeated scan simpler. SmartScan is also designed with a cleaner, more intuitive user interface from ground up, making it easier to use, even by those without special training.

PARK SMARTSCAN REPRESENTS A NEW GENERATION OF AUTOMATED AFM TECHNOLOGY

Park SmartScan is the first of a new generation of AFM technology bringing AFM technology to the masses. SmartScan makes powerful nanoscale imaging technology more efficient and easier to use by automating processes that once required careful oversight by highly trained professionals. This allows much higher research and engineering productivity and greatly reduced labor costs. It also reduces the risk of human error by offering a highly repeatable and accurate means of nanoscale imaging. This sets a new standard for AFM technology and heralds a new generation AFMs.