“PARK ATOMIC FORCE MICROSCOPY (AFM) PLAYS AN IMPORTANT ROLE IN OUR 3-D PRINTING PROJECTS IN THE LABORATORY. THIS POWERFUL TOOL IS CAPABLE OF LOOKING AT THE SURFACE PROFILE OF 3-D PRINTED OBJECTS CREATED BY DIFFERENT 3-D PRINTING TECHNOLOGIES IN NANOMETER RANGE.”

The 3-D printing industry is being hailed as the next industrial revolution, poised to transform every industry and innovate new ones. New studies point to the 3-D printing industry as one of the fastest growing in our economy. In 2014, the 3-D printing industry was estimated to be at $4 billion. With new predictions that 3-D printing will be 50 percent cheaper and up to 400 percent faster, the industry could reach $49 billion by 2025.

But howfast are manufacturers adapting to the new technology, which requires investment and retraining? Experts predict that 93 percent of manufacturers will expand their use of 3-D printing for production parts in the next three to five years and sixty percent of manufacturers expect 3-D printing use to at least double in two to five years.

3-D Printing as a technological feat that started as hobbyists’innovative way of building things has growninto a wellaccepted additive manufacturing (AM) technology. It has now penetrated invarious manufacturing industries such as in electronics manufacturing,bioengineering, food fabrication, and in almost anything we can think of.

3-D printing of electronics

Innovation has paved the way for 3-D printing technologiesin the field of electronics fabrication. With the advances in creating new control systems, techniques such as inkjet and aerosol printing are primarily used for fabricating homogeneous structural electronics. 3D printing has shown a great potential in the electronics fabrication industry as well when it comes to fabricating multiple layer complex electronics.

Can 3D printing potentially become the most viable method for mass producing electronics? For now, incorporating the traditional pickand- place method of building electronics with the latest 3-D printing technologies could be a workable strategy. In this case,to be able to reduce the whole volume of a conventionallymanufactured device, the space occupied and the materials used to build it should also be reduced. In the future, it becomes more and more practical to accurately embed electronic components with conductive interconnects within a three-dimensional substrate as an approach for a more robust and space-saving model.

“According to the 2016 Markets and Markets analysis report, printed electronics, in general, was considered to have a market value of 3.13 billion US dollars at the end of 2015 with a potential to reach 12.10 billion US dollars in the coming decade. But for 3D-printed electronics alone, it was valued 20 million US dollars in 2015 according to Harrop, the director of IDTechEx research firm. Asia Pacific market accounts the largest piece of the market in 2016 where the centers of electronics manufacturing are located in China, South Korea, Japan, and India; therefore, advancing the demand for printed electronics in the said region. Europe, on the other hand, holds the majority of research and development activities, and countries such as UK, Netherlands, and Finland are directing the printed electronics research in the region.”

Optomec, the company that pioneered Aerosol Jet printing, has envisioned the idea of mass production of electronics using integrated 3-D printing approach. While most of the aforementioned companies are outsourcing some of their machine parts (e.g. print heads), Optomec manufactures their own using open systems design for compatibility. The print heads are made compatible with most CNC machines, making it adaptable to any integrated 3-D printing systems for any given production settings.

Taking a unique strategy, their machines can readily utilize commercially available inks rather than solely using their proprietary formulation. Their primary design considerations are focused on printing specialized antennas and sensors. They have printed 3-D sensor for detecting expansion or shrinkage of a turbine. They have also printed interconnects on integrated circuits (ICs) that serve as an alternative to wire bonding process. Aerosol Jet technology is considered superior to existing traditional manners of printing. For instance, it is capable of printing antennas directly on any given surface shape, which is called conformal printing, without the need to use injection molding and laser-based directed printing.With the abovementioned features, Optomec’s Aerosol Jet system is viewed as a key player in the realization of mass production of 3-Dprinted electronics.

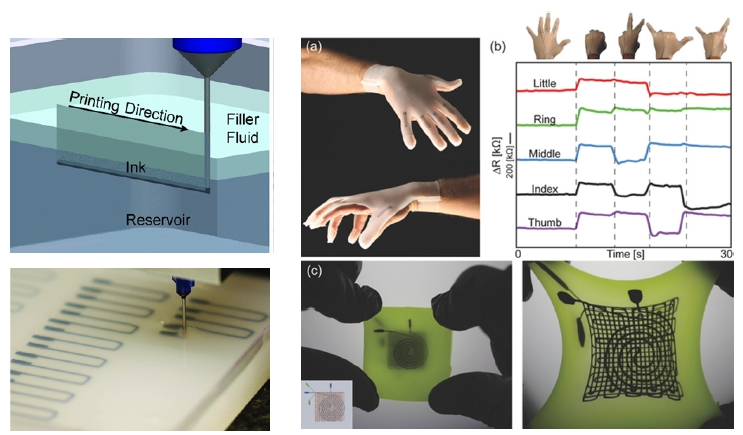

Conductive polydimethylsiloxane (PDMS) has been successfully 3D printed by using a unique embedded 3D printing (e-3DP) method,

as shown.a) A photograph of a glove with embedded strain sensors produced by e-3DP. b) Electrical resistance change at different hand

gestures. c) A three-layer strain and pressure sensor in the unstrained state (left) and stretched state (right).

A three-faced 3D-printed sensing circuit that consists of a plastic tank with circuitry on it was printed by Optomec Aerosol Jet and OEM Neotech Services

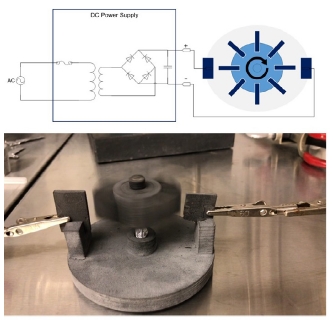

In the area of electrical engineering, attempts have been made to replicate the physical characteristics of metals by 3-D printing functionalized high-performance polymers for applications that require the rigidity and the electrical properties of metallic materials. In this case, electric motors, which are basically made of metallic parts, typically have the abovementioned properties to be able to effectively and efficiently transform electrical to mechanical energy or vice versa. We have successfully demonstrated in our laboratory a metal-free 3-D printed electrostatic motor successfully demonstrated in our laboratory a metal-free 3-D printed electrostatic motor made of polyamide-12 and reduced graphene oxide powders using selective laser sintering technology. By applying DC voltage in the electrodes, the rotor is able to spin at a rate proportional to the electric field created at the electrodes, thus, this is also called capacitor motor. With the transition to building an object with near-metallic properties using 3-D printing and functionalized materials, 3-D printing technology and novel material preparation have really set another standard in the field of manufacturing process.

The photo shows a spinning 3-Dprinted electrostatic motor. The rotor blades and the electrodes were made of processed conductive PA12 with reduced GO while the base was printed using pure PA12.

The photo shows a spinning 3-Dprinted electrostatic motor. The rotor blades and the electrodes were made of processed conductive PA12 with reduced GO while the base was printed using pure PA12.

3-D printing of silicone

Printing of paste mixtures or viscous solutions will become a trend in the future along with the need for building freedom for complex shapes and geometries in manufacturing flexible materials. A broad array of functionalities has been demonstrated by flexible electronics. This unique category of electronics has already been playing an important role in manufacturing solar cells, displays and LEDs, sensors, and thin-film transistors. Flexible electronics has been a trend due to its application in flexible displays and wearable electronics.

Conductive polydimethylsiloxane (PDMS) has been successfully 3D printed by using a unique embedded 3D printing (e-3DP) method, as shown. a) A photograph of a glove with embedded strain sensors produced by e-3DP. b) Electrical resistance change at different hand gestures. c) A three-layer strain and pressure sensor in the unstrained state (left) and stretched state (right).

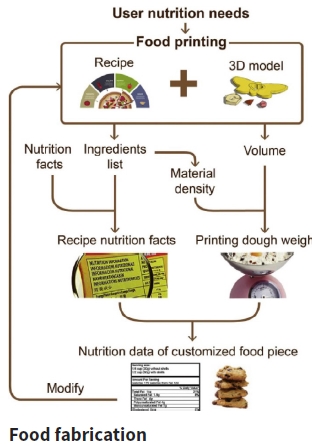

Park Atomic force microscopy (AFM)plays an important role in our 3-D printing projects in the laboratory. This powerful tool is capable of looking at the surface profile of 3-D printed objects created by different 3-D printing technologies in nanometer range. One example is accurately profiling the width of the extruded strands and the height of the layers of a 3-D printed silicone adhesive via high-resolution paste extrusion technique. This measures the consistency of the resolution set all throughout the 3-D printing process. Moreover, shrinkage and other defects can also be examined which can be correlatedto the build parameters of the 3-D printers. This helps identify significant adjustments of parameters for optimizing the build processand reduce defects found in the 3-D printed objects. Unlike other microscopy techniques, AFM does not need treatment of the sample that may cause damage to A rising technology in food fabrication called extrusion-based food printing uses the same mechanism as paste extrusion printing but is specifically intended for building food products using edible materials in a layer by layer manner. Researches have been conducted in 3-D printing food products with the ability to have nutritional control. The 3-D printing technique has been correlated to the produced food texture, and the tunability of nutritional content in the food product, based on 3-D printing extrusion mechanisms. 3-D printing in this field has truly revolutionized the way food is designed and fabricated.

Schematic of 3-D printing of food with nutritional control.

Sustainability

3-D printing market is seen to grow 500% in the next 5 years, reaching around $16.2 billion by this year given the rise of 3-D printer and materials sales worldwide. “It has now moved from a new and much-hyped, but largely unproven, manufacturing process to a technology with the ability to produce real, innovative, complex and robust products.“ Thus, it is one of the fastest evolving markets to date. There’s no question on its potential success due to its high level of customization, its ability to suppress replacement buying, curbing down material waste in manufacturing process, the idea of free sharing of digital designs online, and lessening carbon emissions by eliminating the need for transporting actual products. However, the big question is: how about its sustainability? The flip side would be: power consumption will increase with respect to production, there will be rise of single-use plastic production and usage, there will be introduction of strategized obsolescence of products, possible intellectual property theft due to replication of designs, and the dramatic increase of product consumption will happen, which possibly raise ethical issues on the environment and on creating products and their actual use (e.g. guns, food restrictions, etc.). With the observance of circular economy as a basis for writing energy and waste management policies, initiatives around the world are being concretized towards reducing plastic wastes by recycling them with the aid of 3-D printing technologies. Although, the future is still unclear for a technology in its infancy stage, there are no assurances. Scientists and lawmakers are working hand in hand towards realizing sustainable development for 3-D printing. Time will come that additive manufacturing will surpass traditional manufacturing. When this time comes and the 3-D printing technology comes to an age, us – main consumers – are expected to take responsibility for the lives of the future generation, not just for the sustainability of the technology itself.

IN 2014, THE 3-D PRINTING INDUSTRY WAS ESTIMATED TO BE AT $4 BILLION. WITH NEW PREDICTIONS THAT 3-D PRINTING WILL BE 50 PERCENT CHEAPER AND UP TO 400 PERCENT FASTER, THE INDUSTRY COULD REACH $49 BILLION BY 2025.

References

B. Cook, B. Tehrani, J. Cooper, S. Kim and M. Tentzeris, "Integrated printingfor 2D/3D flexible organic electronic devices," Handbook of Flexible Organic Electronics, pp. 199-216, 2015.

G. Weiderrecht, Handbook of Nanofabrication, Elsevier, 2009.

R. Mosses and S. Brackenridge, "A novel process for the manufacturing of advanced interconnects," Circuit World, vol. 29, no. 3, pp. 18-21, 2003.

D. Zhao, T. Liu, Z. Lin, M. Zhang, R. Liang and B. Wang, "Fabrication and characterization of aerosol-jet printed strain sensors for multifunctional composite structures," Smart Mater. Struct., vol. 21, no. 11, 2012.

B. Lu, D. Li and X. Tian, "Development Trends in Additive Manufacturing and 3D Printing," Engineering, vol. 1, pp. 85-89, 2015.

Y. Shirasaki, G. Supran, M. Bawendi and V. Bulović, Nature Photonics, vol. 7, pp. 13-23, 2012.

E. Macdonald, R. Salas, D. Espalin, M. Perez, E. Aguilera, D. Muse and R.

Wicker, "3D Printing for the Rapid Prototyping of Structural Electronics," IEEE Access, vol. 2, pp. 234-242, 2014.

E. Macdonald, "Integrating stereolithography and direct print technologies for 3D structural electronics fabrication," Rapid Prototyping Journal, 2012.

J. Lewis and B. Ahn, "Three-dimensional printed electronics," Nature, vol. 518,pp. 42-43, 2015.

L. Teschler, "Your next circuit design could be fabricated on a printer," 13 November 2015. [Online]. Available: http://www.powerelectronictips.com/ your-next-circuit-design-could-be-fabricated-on-a-printer/. [Accessed 22

June 2017].

M. Clinch, "3-D printing market to grow 500% in 5 years," 1 April 2014. [Online].

Available: https://www.cnbc.com/2014/04/01/3-d-printing-market-to-grow- 500-in-5-years.html [Accessed 29March 2018].

L. Federico-O’Murchu, "How 3-D printing will radically change the world,"11 May 2014. [Online]. Available:https://www.cnbc.com/2014/05/09/will-3-dtechnology-radically-change-the-world.html. [Accessed 29March 2018].

A. Mitchell, "3D Printing: Adding a Sustainable Dimension to Modern Life," February 2018. [Online]. Available:https://en.reset.org/knowledge/3dprinting-adding-sustainable-dimension-modern-life-02262018. [Accessed 29 March 2018]

Alejandro H. Espera, Jr. is Assistant Professor, Electronics Engineering Department, School of Engineering and Architecture, Ateneo de Davao University, Philippines and is currently a PhD student at the College of Engineering at Virginia Tech. He was a research fellow in 2017 at the Advincula Research Group, Department of Macromolecular Science and Engineering at Case Western Reserve University, led by Dr. Rigoberto Advincula.

Dr. Rigoberto Advincula is Professor with the Department of Macromolecular Science and Engineering at Case Western Reserve University and Research Professor at the Department of Chemistry and Department of Chemical Engineering at the University of Houston and the current editor-in-chief of MRS Communications. Dr. Advincula is the recipient of numerous awards including Fellow of the American Chemical Society, Herman Mark Scholar Award of the Polymer Division, and Humboldt Fellow. He did Postdoctoral work at the Max Planck Institute for Polymer Research and Stanford University and has published over 380 papers, including 195 peer-reviewed publications, 11 patents (and pending), and has co-edited the book on Functional Polymer Films, Polymer Brushes,and New Trends in Polymer Science. For more information go to: http://www.rcapoly.net

Polymers and 3D Printing Event in Houston

Dr. Advincula is hosting a two-day Polymers and 3D Printing Conference Nov. 1-2, 2018 in Houston TX. This conference will connect real-world applications with basic technology covering many topics including the fundamentals of polymers, 3D printing technology, characterization techniques, coatings and finishes for 3D Printing, thermomechanical evaluation and 4D Printing and beyond. This will be a two-day Conference- Training meeting and premiere networking event that will draw participants from many in the industry: chemical companies, academia, coatings experts, formulators, and applicators. For information on registration go to www.poly3d.org